Functionality

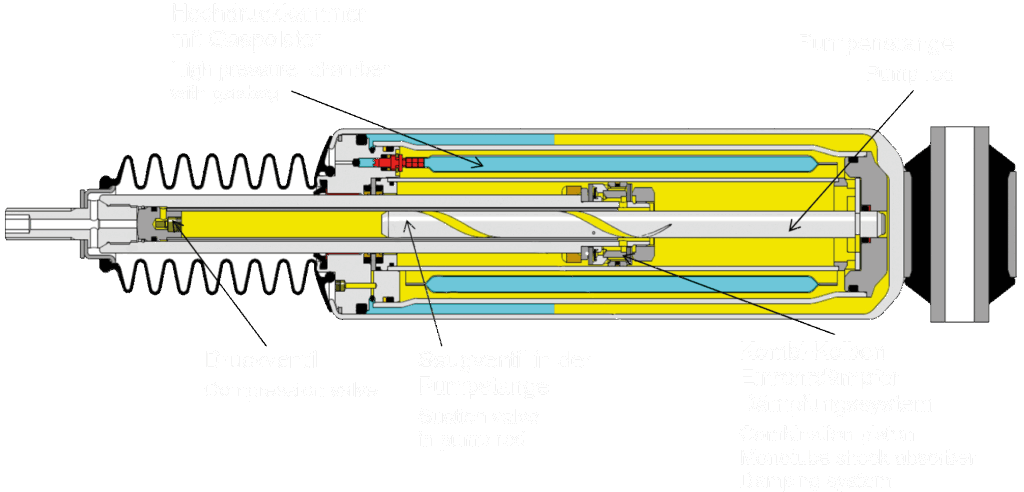

The basic structure of the Nivomat system consists of two separate oil chambers, a monotube damping system, and a pump rod with control sleeves including valves.

The oil chambers are divided into a low-pressure chamber, which serves as an oil reservoir, and a high-pressure chamber with an integrated gas cushion.

When the shock absorber is loaded and the vehicle compresses, the pump rod automatically pumps oil from the low-pressure to the high-pressure chamber through the relative movement caused by road irregularities acting on the Nivomat. The resulting pressure increase acts on the piston rod, which then extends the shock absorber again. This pumping process continues until the motorcycle returns to the predefined ride height — the Nivomat thus automatically adjusts the ride height after about 300 meters of riding.

1.

The LDC Nivomat system is preset to immediately settle into the intended (defined) ride height of approximately one-third of the total suspension travel when riding solo. In this state, the system provides a reduced spring rate and damping compared to a conventional shock absorber, ensuring maximum comfort without any bouncing or oscillation.

2.

A load from a passenger and/or luggage causes the vehicle to sag significantly and negatively affects the vehicle’s geometry.

With a “normal” shock absorber, the spring would need to be preloaded in this case — but this only adjusts the ride height. The necessary adjustment of the spring rate does not take place.

3.

After driving about 300 meters under load, the LDC shock absorber brought the vehicle back to the defined level.

The internal pump rod has transferred oil from the low-pressure chamber to the high-pressure chamber.

The increased high pressure raises the vehicle to the defined ride height while simultaneously adjusting the spring rate and damping to match the load. Ride height, vehicle geometry, spring rate, and damping are optimized throughout the entire ride, ensuring maximum comfort and riding safety.

Many thanks to 1000PS!

Our friends at 1000PS took a close look at our Wilbers Nivomat and explained it clearly in this video. We're delighted with the fantastic presentation and would like to say: thank you for showcasing our suspension so impressively!